Industrial Estate, Muzaffarnagar, Uttar Pradesh

- GST NO. : 09AGSPA6716B1ZI

Products

Silicon Based Anti-stripping Additive

Nano-technology based Anti-stripping Additives are the latest innovation in asphalt road construction technology. Having the space age technology and acting as an adhesion promoter / water proofing agent, these additives utilize the bond formation at molecular level, so they are low dose products with ultimate thermal stability.

Our Nano-technology products work on synergistic combination of molecular amine and silicon acting as reactant as well as facilitator for active bridge formation between road aggregates and bitumen. The bond formation by these additives are very stable and provide a very long water protection for the treated surface.

Mode of action :

- Nano-technology based Anti-stripping Additives are based on silicon and amine molecular chemistry. These products assist in formation of a non-reversible covalent bond between bitumen and silica present in road aggregates. Since this bonding is at molecular level, it is one of the toughest in present day chemistry, which is resistant to the action of higher temperatures or water.

- When these innovative Nano-technology products are mixed with bitumen, the polyamine groups react with organic acids present in bitumen and create a basic environment beneficial for stronger bitumen-aggregate bond formation and molecular reactive silicon forms complex silicon bridge intermediates.

- When the Nano-technology anti-stripping additive treated bitumen is mixed with common road aggregates, the active silicon bridge intermediates in bitumen readily form covalent bond with nearest silicon molecules on aggregate surface. This bond is physically and chemically resistant so it does not allow ingress of water between bitumen-aggregate interfaces.

- Since the active silicon bridge formation takes place at molecular (Nano) level, a small dose of these products are enough to achieve complete protection from water damage.

Conventional Anti-stripping Agents

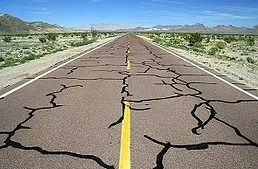

The Premature failure of Bituminous Pavements due to action of water is the most common problem and single biggest factor causing early pavement distress. The most important reason contributing to this condition is improper adhesion between bitumen and commonly used aggregates, salt contamination of water/soil and water drainage problems. Majority of aggregate show high stripping value (as high as 70%) and most of them fail miserably in bitumen adhesion properties. These conditions prevail across continents, thus all around the world, anti-stripping agents are recommended and used to extend pavement life.

Warm-mix is a form of Hot-mix Asphalt produced and laid at lower than recommended HMA temperatures to decrease fuel consumption, reduce green house gases and to achieve same degree of mix compaction even at lower temperatures. The additives used for this purpose are called Warm-mix additive and they include a range of chemical and wax based products.

During initial evolution of warm-mix concept, most of the additives contained water to achieve “foaming” of bitumen resulting in warm mix properties. These additive carried a number of problems like uncertain results, induced stripping, tedious process, increased oxidation and premature failure of pavement, human health hazard etc.

With advancement of technology, fat, chemical and wax based meltable solid type additives were introduced by many reputed organizations with varied levels and advantages in terms of dose, emission, field performance, stripping and oxidation control etc.

In latest of Warm-mix technology, very high performance liquid additives were introduced with advantages of low dose, easy mixing, safe handling, maintain temperature during haulage, outstanding control of stripping, minimized oxidation, cost effective etc. “WETBOND-WMA” liquid is the shining star of this category of low dose, high performance additives with unique feature of being non-hazardous.

In normal atmospheric conditions, Bitumen and water can't mix and will separate instantly. Emulsifiers are speciality chemicals used to stabilize the fine dispersion of bitumen droplets in water. Depending on their chemical properties, emulsifiers are of two major types: Cationic and Anionic.

Cationic emulsifiers provide a fine emulsion under strong acidic conditions, where normally concentrated hydrochloric acid is used for adjustment of final pH.

On the other hand Anionic emulsifiers provide a stable bitumen emulsion under strong alkaline condition, where normally Sodium Hydroxide is used for adjustment of final pH.

The emulsifiers can be ionic products which require neutralization/ Acidification/ Alkalisation at the time of emulsion production or can be a pre-neutralized and pH fixed (Ready), requiring no acid / alkali at the time of bitumen emulsion production.

CATIONIC EMULSIFIERS :

- Cationic emulsifiers are used to produce the large volume and most popular type of Bitumen Emulsions called "Cationic Bitumen Emulsions". These are the most commonly used Bitumen Emulsions in the world for road and highway applications.

- The bitumen droplets in Cationic Bitumen Emulsions carry a positive charge, so special type of low dose emulsifiers are used for their production which are generally treated with concentrated hydrochloric acid in water phase for their "activation".

- There are two broad range of Cationic Emulsifiers: Conventional (which require neutralization with HCl) and Ready (Ready to use product without modification) Emulsifiers.

- These emulsifiers are further divided into Emulsifiers for Rapid / Medium Setting Cationic Bitumen Emulsions and Emulsifiers for Slow Setting Cationic Bitumen Emulsions. The details are given below:

“Wetbond-REX” is a performance grade liquid rejuvenating additive for RAP based hot mix pavements. This is a versatile product which combine properties of Rejuvenation of old oxidized asphalt (present in RAP), Anti-stripping (Water damage protection) and Warm mix asphalt (better compaction on below normal compaction temperatures).

Due to continuous exposure to environmental factors like UV radiation from sunlight, frictional heat generated from moving traffic tyres, freeze thaw, regular change in day and night road temperatures, deposition of clay, sand and other mineral substances on road surface and natural aging process of Bitumen, the bitumen used in construction of asphalt pavements becomes oxidized and brittle over a period of time. This results in loss of flexibility of asphalt layers, formation of cracks, potholes and finally complete failure.

An important factor contributing to brittleness is loss of maltene part of bitumen which chiefly consists of resins, oils, oleifins, naphthenes, and natural polymers. During recycling of asphaltic pavements, a substantial quantity of Reclaimed asphalt (RAP) is produced which is generally wasted in the form of landfills. However by using a liquid rejuvenating additive capable of replenishing the lost maltene part and by adding a little quantity of fresh bitumen to this RAP, the same can be reused for fresh paving and provide a lot of savings in terms of materials, time and money.

Micro-surfacing is a high performance cold applied thin layer bituminous surfacing which is used for preventive maintenance and renewal treatment of flexible and rigid pavements. Since this technology is applied in thin layer even for high traffic roads and highways, it requires a special grade of Polymer Modified Bitumen Emulsion (PME) which rectifies surface defects including minor cracks, dry & hungry surfaces, wear and tear due to traffic movement.

Also micro-surfacing is a quick traffic technology where its components are mixed and laid on road in single step process using special pavers, the Polymer Modified Bitumen Emulsion is custom made based on physical, chemical properties of aggregates, weather conditions and type of grading of aggregates. When applied on road, this PME sets fast, build cohesion quickly and allows opening of traffic within 1 hour.

Petrochem Specialities had over 14 year experience in formulation of project specific Polymer Modified Micro-surfacing Emulsions using different types of high performance emulsifiers, variety of latex polymers and other performance additives. With well equipped laboratory having special testing equipment like Cohesion Tester, Wet-track Abrasion Tester, Schulze Breuer Tester, Boiling water Stripping Value apparatus, Consistency tester etc, we ensure best in class materials for our customers.

Modification of Bituminous products requires addition of an ingredient which changes the rheological properties specially elasticity, resistance to wear deformities etc. “CATLEX” is the cationic latex of Natural Rubber, which gives excellent cohesion properties and compatibility with Bitumen and emulsions. This Latex provides a better alternative to synthetic rubbers due to its better elastic properties and superior field performance required for cold mix bitumen technologies including micro-surfacing.

“CATLEX” is chemically modified and stabilized form of natural rubber latex.

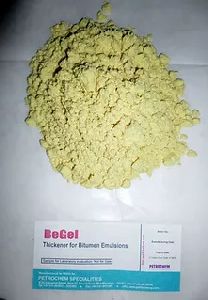

Thickeners are natural or synthetic substances which are used to increase the viscosity of a liquid system. A thickener can be liquid or a solid depending on the source of raw material and intended applications.

To increase the viscosity of bitumen emulsions, mostly the residual bitumen is increased which in turn increases the cost to a very high level and require higher dose of emulsifier and other additives. Few emulsifiers claim to increase the viscosity and storage stability of Cationic Bitumen Emulsion but a fine balance of dose is required as low dose do not increase viscosity and a slight higher dose develop lumps in final emulsion causing it to fail in sieve test. Also prolonged storage of Bitumen Emulsion in open under hot and cold conditions cause the Bitumen Emulsions to cream (separation of water and formation of hard bitumen layer) and site dilution of Bitumen Emulsions by road contractors causes the breaking of emulsions which are serious issues for emulsion manufacturers.

Cationic Bitumen Emulsions contains cationic emulsifiers which are stabilized using strong acids like HCl under very low pH. Most of the natural and synthetic thickeners are not stable on this pH and disintegrate within hours of addition causing sharp fall in viscosity. Our products are a class apart.